Many steps are necessary to produce a large-format print product and install it on site. The work processes must be calculated in a commercially clean manner and tacked into production throughout. Often the orders are individually tailored to the customer’s requirements. Sometimes they are just standard jobs for which a detailed print calculation is not worthwhile. ERP software must address these and other special features in large format printing. Five functions are therefore essential for ERP software in large-format printing.

Don’t give anything away: detailed costing in large-format printing

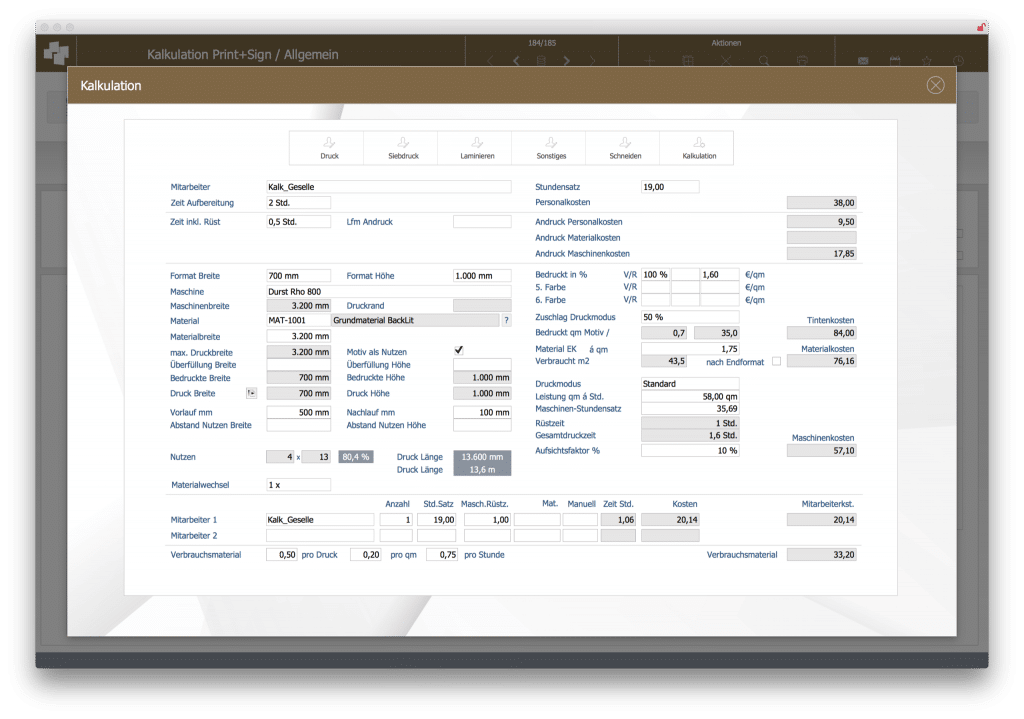

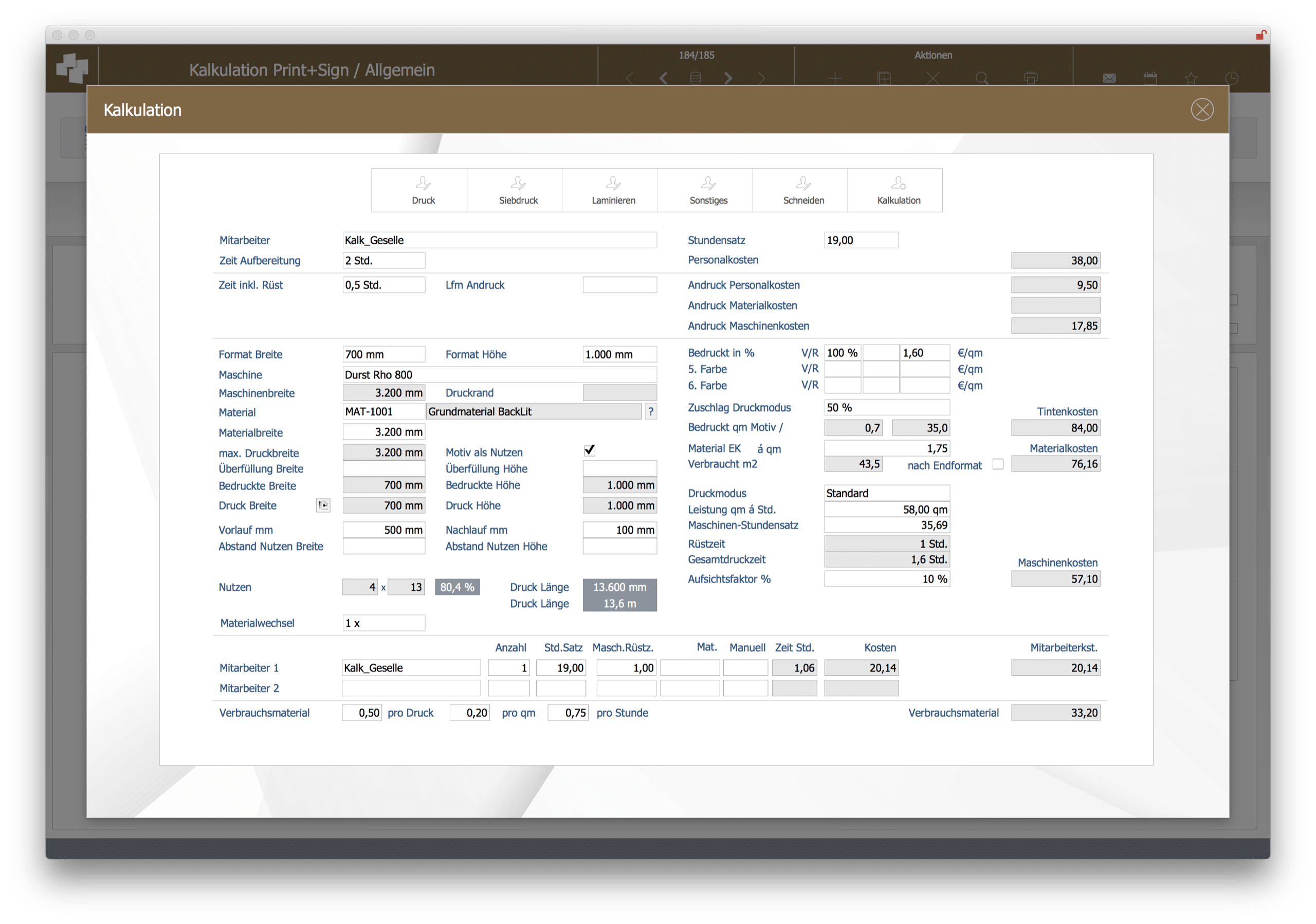

Large format printing is often individual. Is the job worthwhile for the LFP printer? Can I quote the customer a price that will cover myself? Fine calculation means that I take into account all the parameters of a print product, including ancillary costs such as machine costs, electricity, etc., in the pricing. The prerequisite for this is unique and conscientious integration of cost centres, prices but also article descriptions. Once entered, these can be available for all subsequent work steps in further processing or for repeat orders. Margins can be secured and optimised through accurate, realistic, uniform costing.

Not everything is individual: standard calculation in sets

All printers have standard products, e.g. beach flags or roll-ups. Calculating these over and over again is time-consuming. Standard products consist of several parts/materials. Therefore, it makes sense to fall back on fixed sets that quickly list the necessary individual parts of the standard and generate them into an offer.

In addition, with a standardised calculation scheme it is possible to better limit the number of variants. It is irrelevant which employee in the company does the calculation. The same standard applies to everyone.

Seeing live what is going through: production planning

Production planning transmits jobs directly to production according to priority and trade without detours. The status quo of the print job is visible live to everyone in the company, for example via a traffic light system. This means that customer service staff can always check the latest status in the system and take the customer’s wishes into account.

Automation makes the difference: interfaces to third-party suppliers

In times of digitalisation, ERP software for large-format printers should basically be able to interface with all external systems. These can be online shops, B2B ordering systems or industry-specific systems such as RIP software. It is important that data is reliably synchronised from one system to the other. Fully automatically, of course.

Save costs, secure margins and expand: Evaluation per cost centre

In large-format printing, as in related areas such as signage, textile printing or signage, many different trades are involved. For the management it is important to have controlling at cost centre level in order to analyse and, if necessary, optimise the performance of the individual departments.

Continuous business processes in large-format printing

ERP industry software is characterised by consistency. Particularly in printing operations, the individual trades, including administration, must work together. A job should therefore be routed through the company like a digital handout and avoid multiple work. This enables a consistent and uniform level of information and communication.

Conclusion

Compared to industry software for printers, standard ERP software cannot compete without extensive customisation. Large-format printing, with its additional work steps that “surround” the actual printing, is a particularly big challenge for ERP software. That is why a compromise solution is the less favourable path for most large-format printers.

Current articles and user reports

advanter special – Workflow integration in digital and large format printing

Seamless integration of all systems involved is essential for the perfect process. Find out, what workflow integration can mean for your processes in our new advanter special.

advanter special – Logistics in print companies

Today more than ever, it is essential that print companies monitor their logistics costs, identify potential efficiency improvements and realise cost savings. Because there is often important optimisation potential hidden in these areas too….

advanter special – production planning in print companies

When it comes to production planning in print companies, numerous factors need to be taken into account and optimally coordinated. Digital support is often essential for efficient planning.

advanter special – calculation in print companies

As modern calculation software, advanter supports the fast and efficient calculation of your orders. It also offers a wide range of options for optimising your processes and improving your margins.